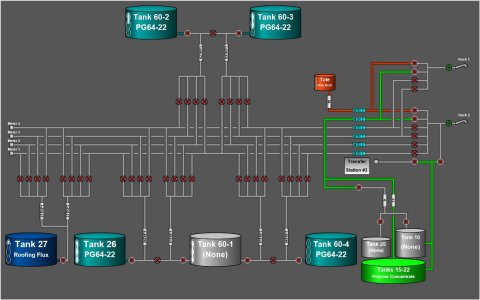

Our Products

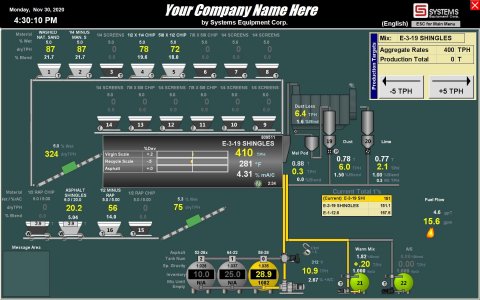

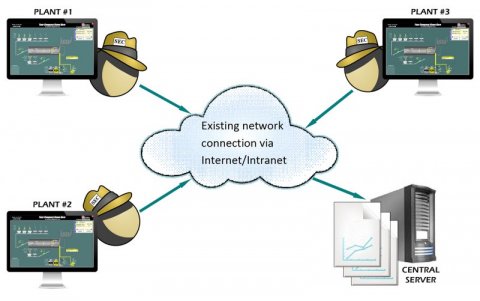

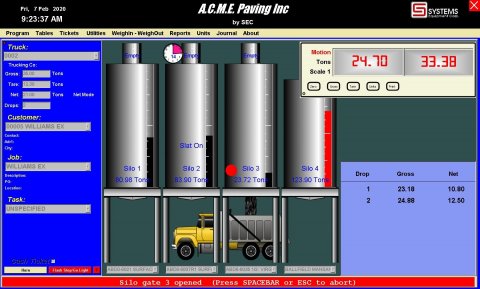

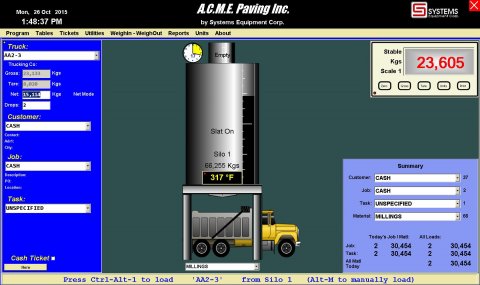

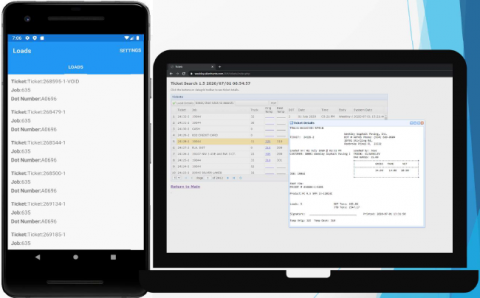

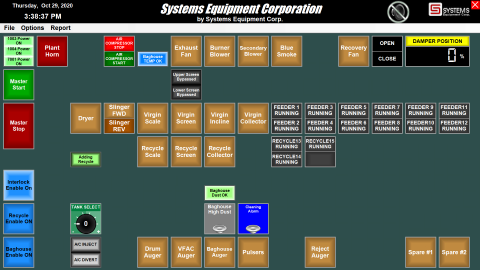

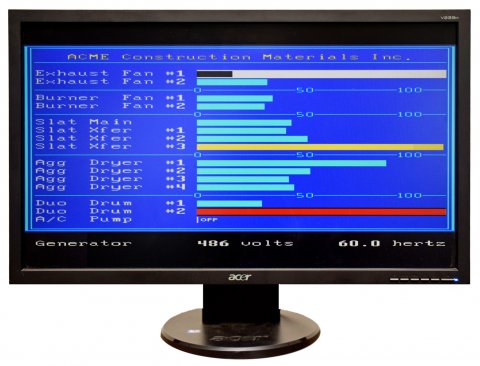

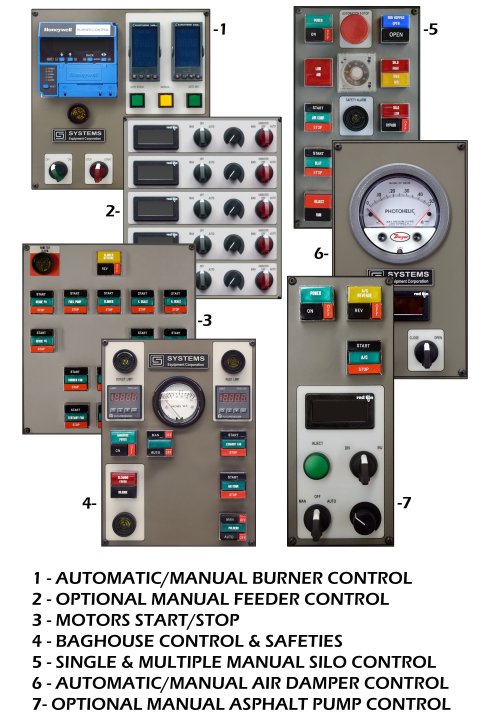

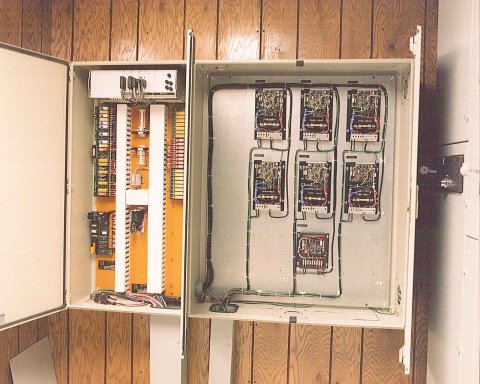

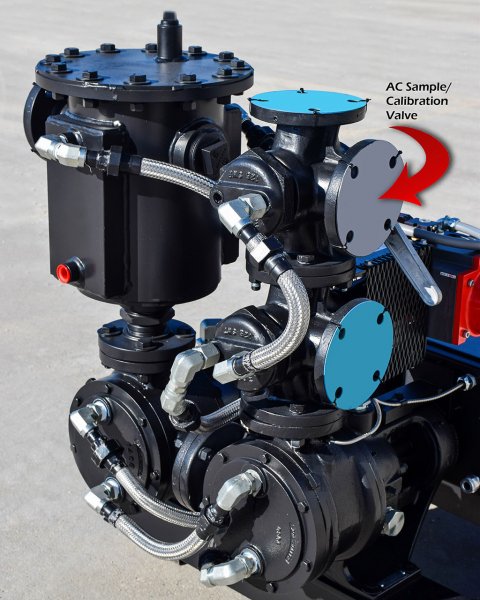

SYSTEMS has been manufacturing a complete line of controls and control-related components for the asphalt and aggregate industries since 1987. It includes electrical, mechanical, control, and software products. We have scale house, control house / control center, asphalt controls, asphalt automated systems and asphalt components. Our products are in use worldwide. We sell through dealers, select original equipment manufacturers, and factory direct.